With our track record of many successful projects in industry sectors ranging from International and local mining houses, Airports to prestigious shop fitters, signage companies and kitchen companies. Our diverse portfolio of equipment and skills makes us flexible enough to handle any project be it a small fabrication job to a major manufacturing and installation project.

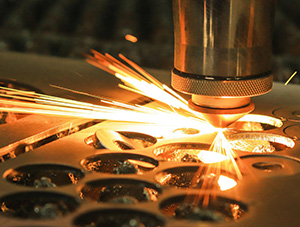

We have a very well-equipped large factory of 10 000 under roof sq meter, with all the modern metal working equipment like, laser cutting, high-definition plasma cutting and large format profile cutting. This combined with our CNC bending, rolling Tig and Mig welding for sheet metal products as well as engineering machinery, CNC Milling and turning including a range of conventional engineering machines we can handle any project big or small. We also offer in house brushing and polishing that can be applied to any metal product we manufacture.

Part of our diversity is our ability to work in a variety of metal, Stainless steel being one of our specialties but also aluminium, copper, brass, mild steel, special steels and expanded metal products. We also fabricate to design structural and tubular structures to customer specifications. All can be processed under one roof. This is our offering to our customers to build close long-lasting relationship so to give them the edge and make then successful in the market with peace of mind that the work will be done right.

![]()

MINING HOUSES

![]()

AIRPORTS

![]()

SHOP FITTERS

![]()

SIGNAGE COMPANIES

![]()

KITCHEN COMPANIES

![]()

CONSTRUCTION COMPANIES

To support our customers, we have teams of experienced installation engineers to make sure the products we manufactured are installed timeously and efficiently to further back-up the quality of products we supply.

We can produce or manufacture to design or drawings any product in stainless steel, aluminum, brass, copper, chromadek, galvanized and mild steel.

CNC BENDING

PLASMA CUTTING

LASER CUTTING

MIG WELDING